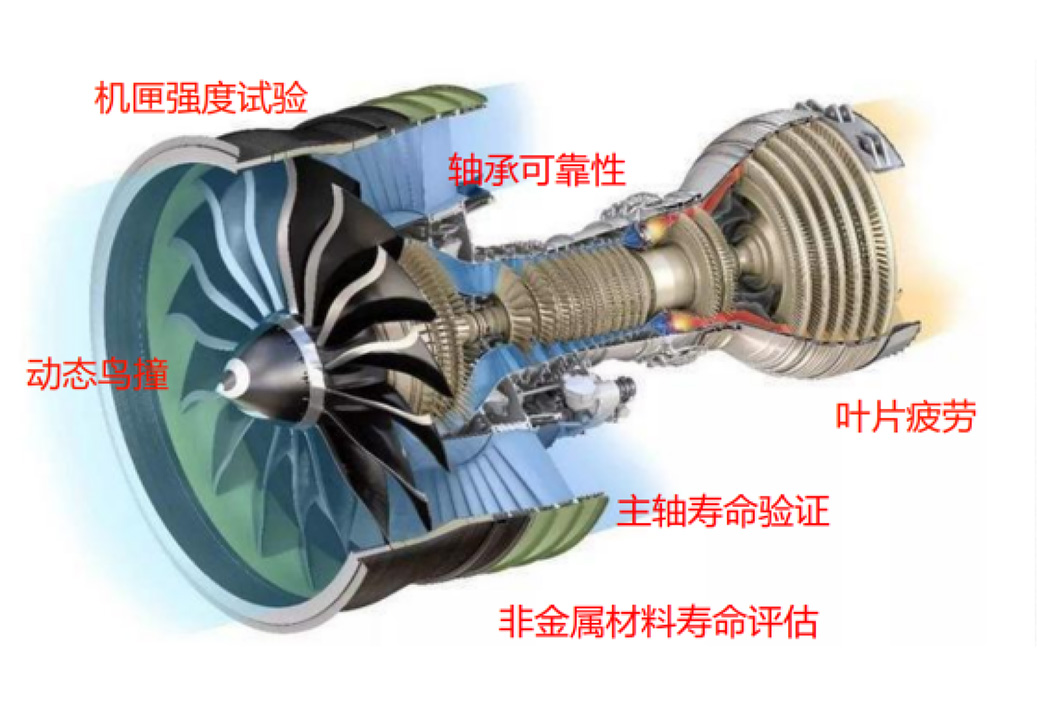

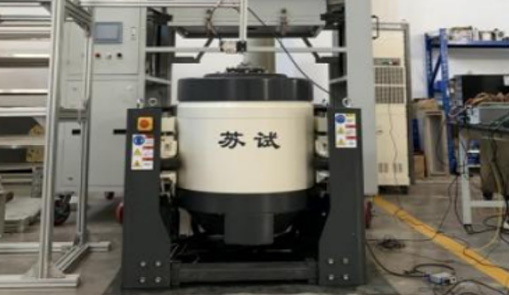

The first domestic bird impact test equipment with rotation developed by Su Shi Group (equipped with 3 high-speed cameras and a vacuum chamber inner diameter of 3600mm) was used to conduct bird impact tests on full-size fan blades under rotating conditions, in order to obtain dynamic and unbalanced responses of fan blades, setting a precedent in the industry In addition, it is also possible to carry out tests including engine spindle life (16 channel coupled loading (1T-20T), 16 full bridge strain collection (64 channels), pulsating torque of 20000 N · m, bending moment of 25000 N · m, axial force of 60kN, and shear force of 5kN acting on both shafts simultaneously), gearbox strength (4 actuators coordinating loading simultaneously, 12 strain gauges and 24 compensating strain gauges collecting data), blade high-temperature vibration fatigue (fatigue laser displacement sensor (0-50mm); Temperature range: 1100 ℃ MAX, as well as finite element calculation and non-metallic material life assessment services for gas turbines

Box strength test

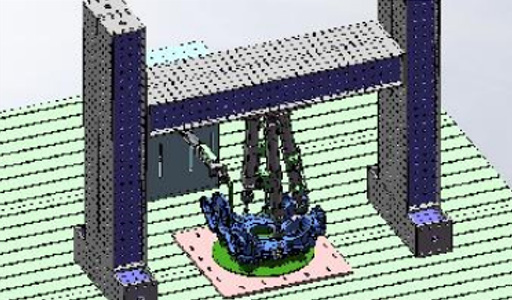

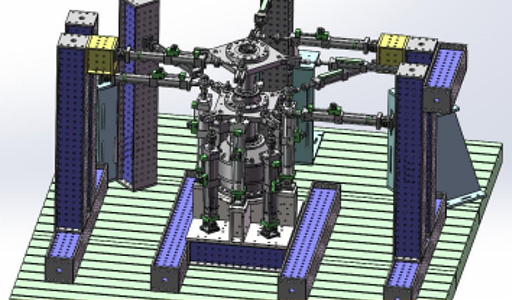

Engine spindle life verification

Engine blade rotating bird strike test bench

High temperature vibration fatigue testing system

Reliability life verification of bearings

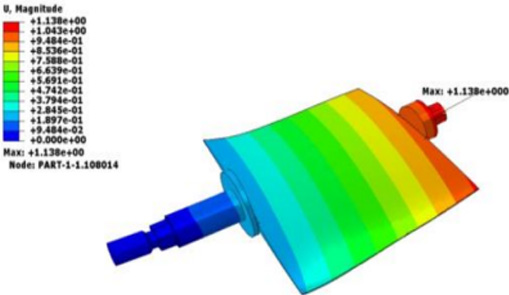

Finite element calculation

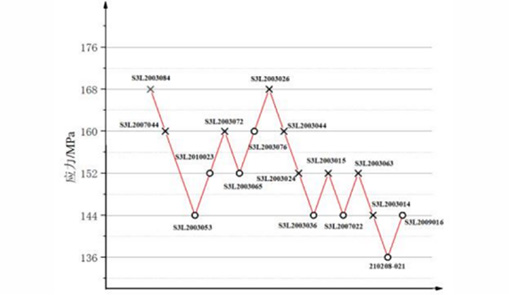

Blade vibration fatigue rise and fall diagram

National Laboratory Network Layout

Integrated Circuit Testing and Analysis Laboratory

Software Evaluation Laboratory

Industry experience and technological accumulation